WELCOME TO

compass & Diamond print solutions

Printing excellence for London and beyond

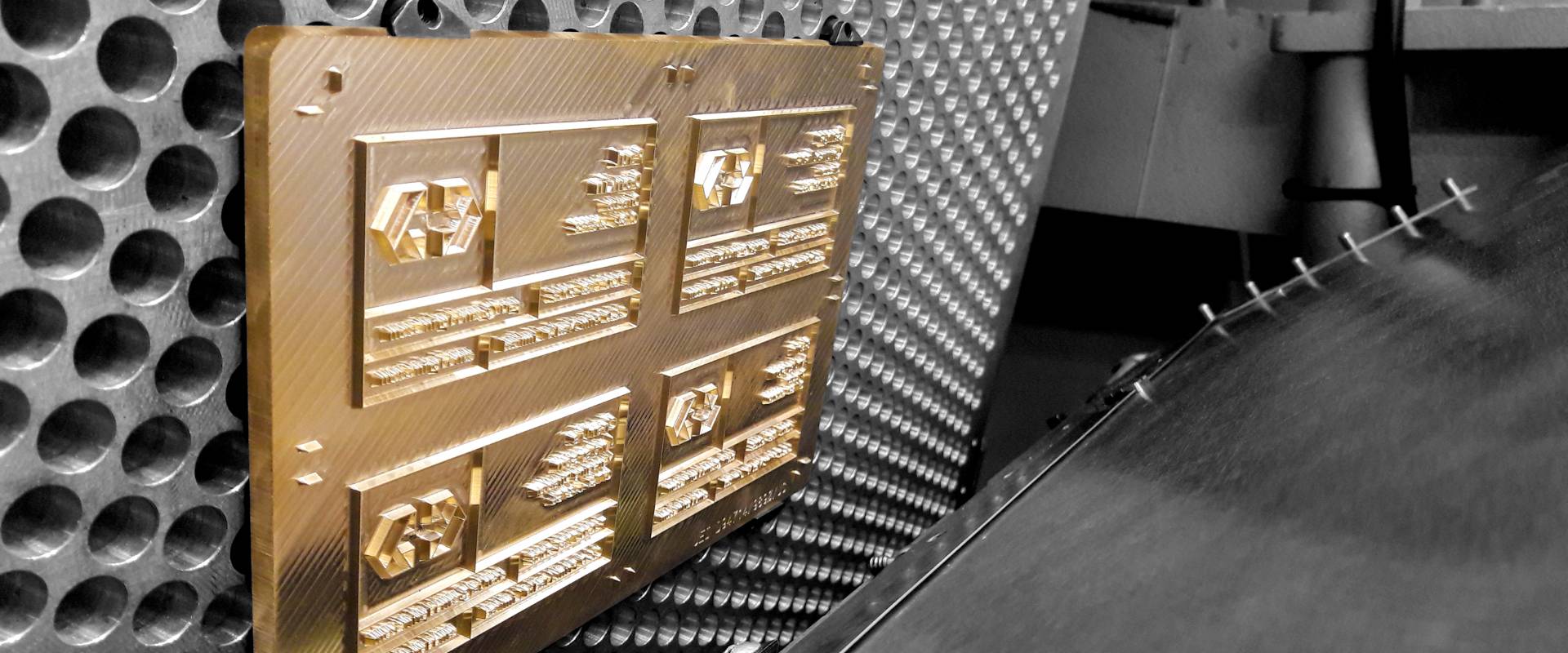

FOUR DIFFERENT PRESSES

UNDER ONE ROOF

Heidelberg Speedmaster SM 74,

HP Indigo 5500, Ricoh Pro C7100SX & Kludge EHD

WANT THE BEST

QUALITY DIGITAL PRINT?

Then it's a job for our HP Indigo digital press

WIDE RANGE OF BESPOKE

FINISHING OPTIONS AVAILABLE

Everything from Duplexing to Saddle Stitching

ONLY FIVE MINUTES WALK

FROM THE TUBE

17-19 Bonny St, London NW1 9PE

QUICK TURNAROUND AND

DELIVERY IN LONDON

We're based in Camden, so we'll get your job to you pronto!

NEW LOOK,

SAME GREAT SERVICE

We've smartened ourselves up a bit

WE CARE ABOUT OUR

ENVIRONMENTAL IMPACT

Check out our impact analysis

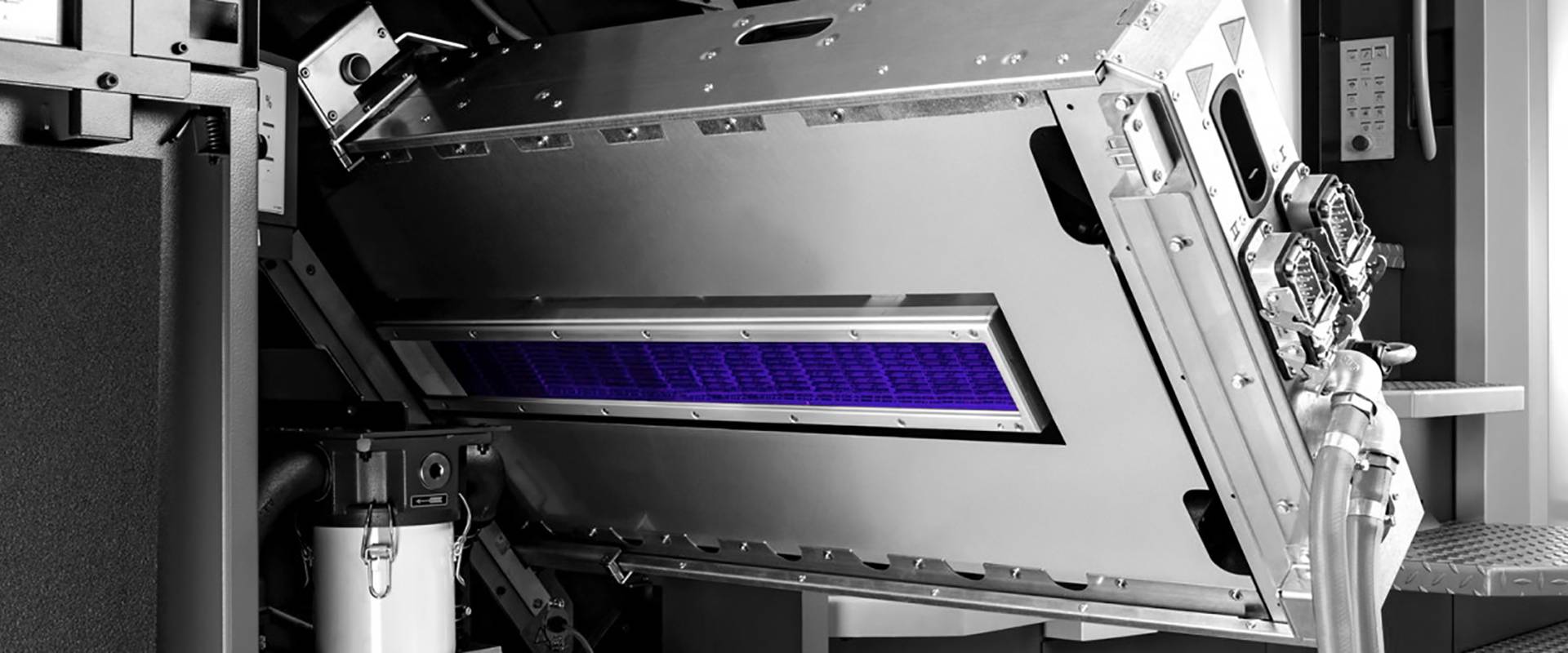

GET YOUR PRINT TODAY

WITH UV LED CURING

Even with high ink coverages, our LED system

achieves the best curing results in sheetfed offset printing.

MADE

IN CAMDEN

Bespoke zero plastic boxes now available,

contact us on 020 7284 3008 for more information.

Compass & Diamond Print Solutions are proud to announce we are now part of Barnard & Westwood Limited – Fine Printers & Bookbinders

With our extensive range of print and finishing facilities, we are able to achieve the best results from our designs or your supplied artwork. The production team can utilise the equipment and their skills to produce the print product of your choice, no matter how big or small. Because we care, and aim for the very best in every job, we’ve earned the trust of all our clients from the small business to the giants such as Selfridges, Diesel, MTV, Ted Baker, Zara Hadid, King’s College and the Natural History Museum … we are your boutique printer without the boutique price tag.

Managing Director, Marshall Harrison Ltd

Marketing Manager, Diesel UK

Chloe Tai, Film Constellation Ltd

Tejinder Jouhal, Hanway Films

Kristina Egan, Darley Anderson Children’s Book Agency Ltd.

Claudia Parkinson, Pandora

Marketing Manager, Diesel UK

Chloe Tai, Film Constellation Ltd

Tejinder Jouhal, Hanway Films

Kristina Egan, Darley Anderson Children’s Book Agency Ltd.

Claudia Parkinson, Pandora

Ricoh digital print technology uses toner based inks and is excellent for producing print where low budgets have to be upheld. It can also print 'white' and 'clear gloss' to enhance your product at a price that doesn't break the bank.

Previous

Film lamination, available in matt, gloss, silk, soft touch and anti scuff. Duplexing, perfect for business cards and invitations. Two or more printed sheets are bonded together to produce a more substantial product. Binding, this finishing process is used for brochures, magazines or booklets. They can be wire bound, saddle stitched (two wires), PUR bound (square back with a spine), or case bound.

Ricoh digital print technology uses toner based inks and is excellent for producing print where low budgets have to be upheld. It can also print 'white' and 'clear gloss' to enhance your product at a price that doesn't break the bank.

Previous

Film lamination, available in matt, gloss, silk, soft touch and anti scuff. Duplexing, perfect for business cards and invitations. Two or more printed sheets are bonded together to produce a more substantial product. Binding, this finishing process is used for brochures, magazines or booklets. They can be wire bound, saddle stitched (two wires), PUR bound (square back with a spine), or case bound.

Ricoh digital print technology uses toner based inks and is excellent for producing print where low budgets have to be upheld. It can also print 'white' and 'clear gloss' to enhance your product at a price that doesn't break the bank.

Previous

Film lamination, available in matt, gloss, silk, soft touch and anti scuff. Duplexing, perfect for business cards and invitations. Two or more printed sheets are bonded together to produce a more substantial product. Binding, this finishing process is used for brochures, magazines or booklets. They can be wire bound, saddle stitched (two wires), PUR bound (square back with a spine), or case bound.

Ten minutes walk from King’s Cross, Russell Square or Farringdon Underground Stations makes same day deliveries inexpensive and turnaround times even faster!

Images

Images should be CMYK and a resolution of 300dpi . Black and White (Mono) files can be either Greyscale or CMYK, if CMYK ensure they are neutral in colour balance. When converting from RGB image file in Photoshop or when creating a PDF from your design program, select the 'ISO Coated V2', profile, this profile is suitable for many printing devices.

Page Layout Documents

Layout designs should be prepared to the final page size plus a 3mm allowence for bleed. All colours used in the layout should be set to print CMYK, special colours using Pantone colours can be specified as spot colours or switched to CMYK. Do NOT change the name of any Pantone colour swatches used within the layout. Supply all graphic files and fonts used within the document. For the best results solid black areas should be made up of the following CMYK breakdown C60 M50 Y50 K100.

PDF Documents

Print Ready' PDF's must be as single pages with 3mm bleed and printers trim marks applied.The page must be centrally located within the PDF. Do NOT include file information tags that cause the printed page area to be off centre. Ensure all required fonts are embedded.

Bleed

For professional designers who understand bleed, please skip this bullet point...Bleed is the area of artwork that has to be extended beyond the page size. Printed material requires additional image area to trim off so any image or colour panel that extends to the page edge will be cut flush without any white edges. A standard 3mm of area is required on each edge, thats an extra 6mm to the width and height of the document, for example: A4 Paper = 210mm x 297mm, + 3mm bleed all round Total Document Size = 216mm x 303mm.

File Delivery

Artwork files that are too big to deliver via e-mail can be sent by an online delivery service. We can send out a link to our Hightail service or accept a link from your own file delivery provider.

Proof

On request a PDF proof will be supplied back to you for approval of content before printing.

Compass & Diamond Print Solutions are lithographic and digital printers operating in a 5,500 sq ft railway arch office in Camden, North London. We primarily produce printed matter for a wide range of clientele in related and non-related industries. We have identified the primary environmental impact of our business to be our electricity consumption and volume of waste paper produced. We wish to demonstrate to our current / future customers and staff our intentions to reduce our carbon footprint.

By monitoring our electricity consumption, we will reduce our carbon footprint by introducing new working practices and updating of equipment.

By monitoring our general and recyclable waste, we aim to improve our recycling performance.

Compass & Diamond Print Solutions will comply with all of it’s relevant legal obligations.

We will continue to monitor and review on a six monthly basis both electricity consumption and waste / recycling. Our staff have been briefed and are reminded by displayed notices as to how they can help reduce are carbon footprint. Our target in the first year is to reduce our carbon footprint (beyond our current achievements) by 10% now that we are monitoring our consumption.

We will look to highlight any working practices / activities that affect are carbon footprint unnecessarily and implement a plan to reduce or eliminate them. We will monitor are general waste to see if any of it can be added to are recycle list.

The Directors will discuss and review our progress every six months. All members of staff will be consulted at that time and the results posted on our web site.

A copy of this policy has been issued to all staff members and also posted on our website.

This policy has been drawn up and will be reviewed every six months by the five Directors of Compass & Diamond Print Solutions. Six monthly reviews will be communicated to all staff members and posted on our website.